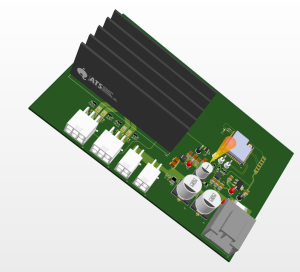

Versatile Multi-Load Motor & Actuator Controller with Integrated ESP32-S3 Wireless MCU

Supported Load Types

- Linear Actuators (Up to 10A, Bidirectional)

- Drive one or two high-current linear actuators with precise bidirectional control (using paralleled outputs for up to 10 A continuous per direction).

- Ideal for industrial and automation applications needing robust, reliable movement.

- High-Current Solenoids or Valves

- Control up to two independent high-current solenoids, industrial valves, or heavy-duty relays.

- Each paralleled output channel supports up to 10 A continuous.

- Brushed DC Motors

- Supports two independent brushed DC motors with full bidirectional speed and direction control (up to 10 A per channel).

- Paralleled outputs allow for higher current and improved thermal reliability.

- Stepper Motor Control

- Full bipolar stepper motor control for one high-current stepper motor.

- Uses both paralleled outputs per phase for extra thermal headroom and reliability—perfect for precision automation.

- Thermoelectric Coolers (TEC/Peltier Elements)

- Drives one or two TEC/Peltier cooling elements.

- Provides precise current regulation, supporting higher current per channel for demanding thermal management applications.

Advanced Features

- True Synchronized Multi-Actuator Control with Hall-Effect and Potentiometer Feedback

Control two linear actuators at once, perfectly synchronized using real-time feedback from Hall-effect sensors or potentiometers. Achieve accurate, repeatable movement—ideal for lift desks, robotics, and custom automation where precise alignment is critical. Advanced closed-loop control ensures both actuators always move together, auto-correcting drift and supporting programmable endpoints for advanced automation. - Motion Presets & Programmable Position Control

Store and recall multiple preset positions directly on the controller. Easily automate movement to frequently used locations with the push of a button or simple command, streamlining repetitive tasks and complex automation sequences. - Integrated Precision Current Sensing & Regulation

On-board current sensing across high-side MOSFETs (IPROPI) for each half-bridge

±3.5% sense accuracy at maximum current

Optional support for external current sense resistors - Flexible Logic & Programmable Control

Separate logic supply (VCC) for system compatibility

Programmable output rise/fall time for optimal EMI performance

Programmable fault recovery for custom protection response

Supports 1.8V, 3.3V, and 5.0V logic-level inputs - Ultra-Low Standby Power

Sleep mode draws less than 3 µA for battery-powered or always-on applications - Comprehensive Protection Suite

Supply undervoltage lockout (UVLO)

Charge pump undervoltage (CPUV)

Overcurrent protection (OCP)

Overtemperature/thermal shutdown (OTSD)

Real-time fault output (nFAULT) pin for system monitoring - Unique 48 V compatibility: Most competing controllers only support up to 24 V; this unit supports the full range up to 60V.

Built-In Connectivity & Intelligence

- Powered by ESP32-S3 MCU with Wi-Fi, Ethernet, and Bluetooth 5.0 LE

- IEEE 802.15.4 (Thread, Zigbee, Matter compatible)

- Secure boot, hardware crypto, and OTA firmware updates

- Real-time status, remote monitoring, diagnostics, and control via web dashboard or app

Typical Applications

- Linear actuator and high-current motor control in industrial, building automation, and robotics

- Valve, solenoid, and relay control in process and automation systems (heavy-duty, high-current applications)

- Thermoelectric cooler (TEC/Peltier) modules in cooling and thermal management applications

- Medical, laboratory, and process automation equipment

- Stage lighting automation, custom machinery, and more

Output Power Specifications

- Per Channel Maximum Output:

Up to 650 W per channel (10A @ 65V DC, with sufficient heatsinking)

480 W per channel (10A @ 48V DC), typical in industrial environments - Total System Output:

Up to 1,300 W combined (2 × 10A @ 65V DC, both channels)

960 W total (2 × 10A @ 48V DC), continuous operation

Potential Enhancements for a True Industrial-Class Controller

Modular & Scalable Design

Enable multi-actuator synchronization, daisy-chaining, or firmware stackability via industry-standard interfaces or bootloaders.

Add Optical Encoder & Reed-Switch Feedback

For ultra-precise, absolute position sensing—ideal for multi-turn applications and ensuring position integrity even after power cycling.

Support Industrial Fieldbus Protocols

Include CAN, RS‑485/Modbus, or EtherCAT to seamlessly integrate with PLCs, SCADA systems, and industrial automation networks.

Onboard Motion Intelligence

Implement features like programmable ramp-up/down, end-stop auto-detection, homing routines, multi-position presets, and embedded PID profiles.

Rugged Housing & Certifications

Design with IP65–IP67 protection, conformal PCB coating, and acquire UL/CE/RoHS certifications to meet industrial safety and environmental standards.

Enhanced Remote Monitoring & IoT

Expand Wi-Fi/Bluetooth capabilities for live telemetry, cloud connectivity, predictive maintenance, and user-friendly mobile or web dashboards.